AquaSPICE

Project Information

Title: Advancing Sustainability of Process Industries through Digital and Circular Water Use Innovations

Funded under: Horizon 2020 (visit Cordis page)

Overall budget: € 12 847 491

Home page: https://aquaspice.eu/

Role of TUC indigo team

TUC brings its extensive experience in process modelling and smart ICT technologies. TUC also develops the AquaSPICE use cases. Finally TUC develops educational courses and material.

George Arampatzis is the Technical Coordinator of AquaSPICE Project.

Project Description

AquaSPICE aims at materializing circular water use in European Process Industries, fostering awareness in resource-efficiency and delivering compact solutions for industrial applications. That challenging aim necessitates (i) fostering the industrial deployment of innovative water treatment and re-use technologies, (ii) closed-loop practices regarding water, energy and substances, (iii) a system for real-time monitoring, assessment and optimization of water (re-)use at different interconnected levels and (iv) an effective organisational, regulatory and business framework. AquaSPICE not only offers these but demonstrates the effectiveness, supported by the breadth of European process industries providing evidence on the achievement of the aforementioned aims.

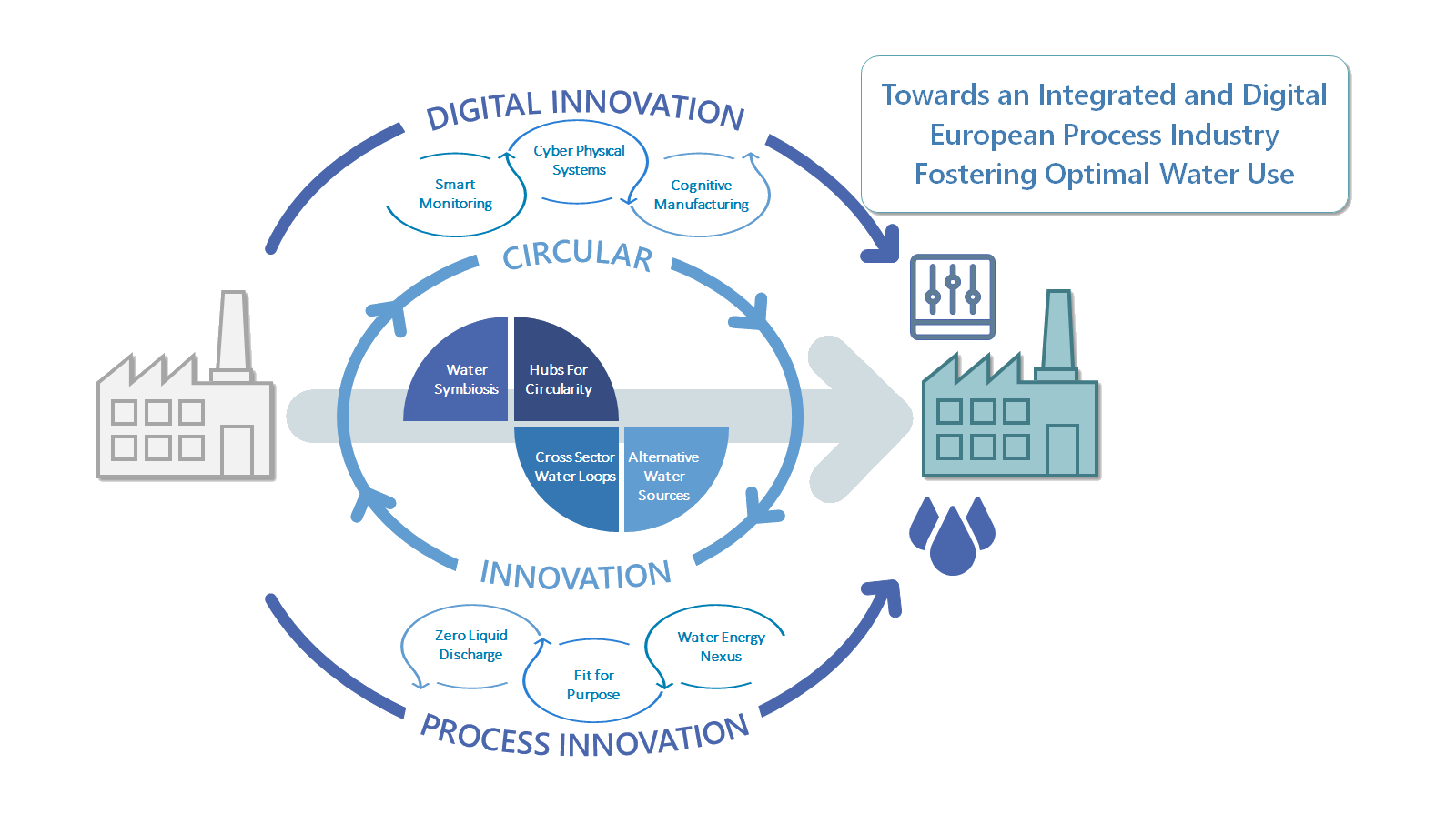

AquaSPICE develops, integrates, demonstrates and offers innovation that transverses three pillars.

i. PROCESS INNOVATION: A comprehensive set of advanced technologies and practices, combining energy and substances

recovery are installed, operated and assessed within AquaSPICE’s case studies, leading to novel solutions for water saving, treatment and recycling. These are diligently selected through background review and case specific needs (a) to bring tangible improvements per case study, while ensuring transferability to many relevant settings in European industries.

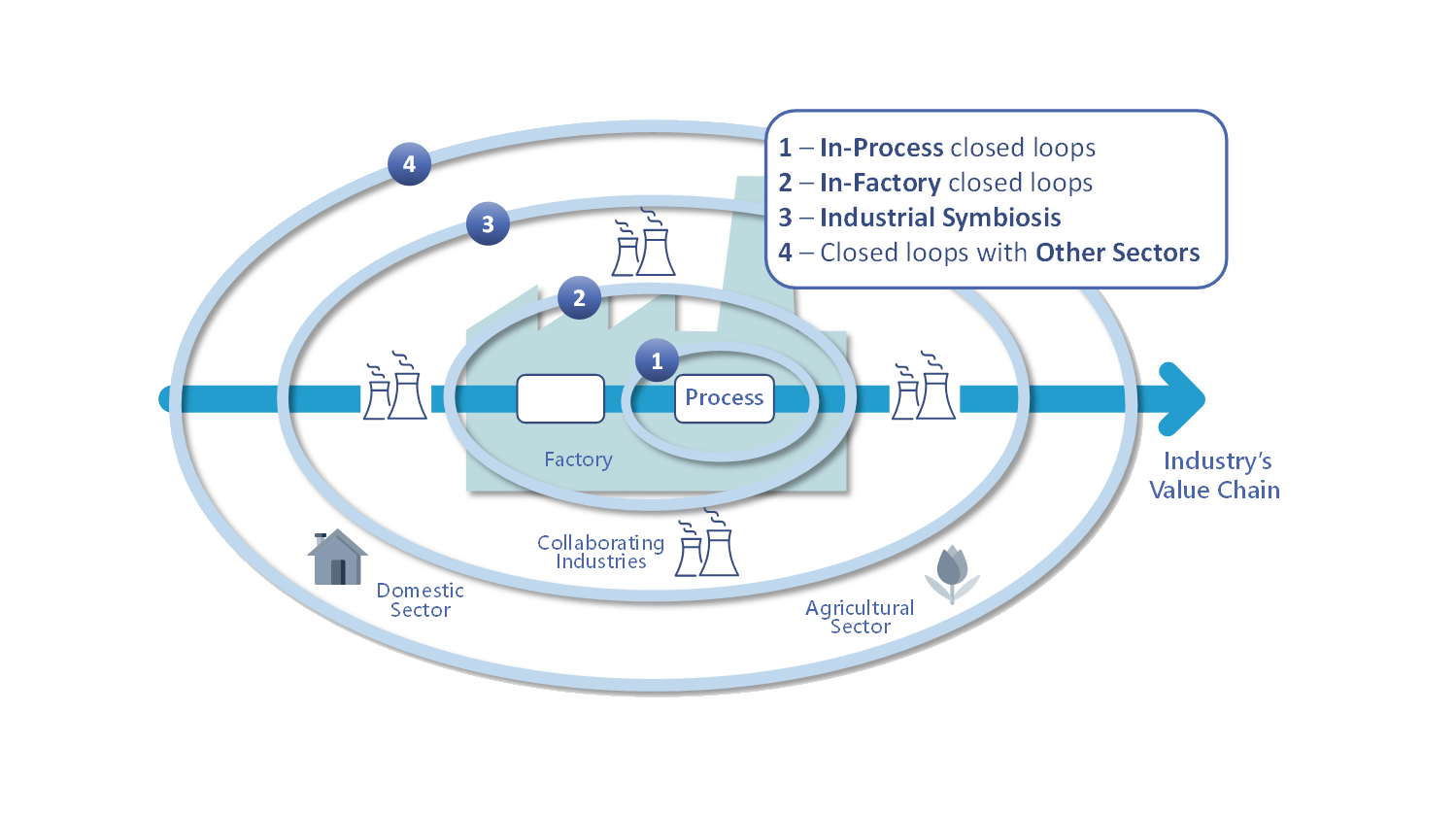

ii. CIRCULAR INNOVATION: Closed-loops including water re-use options at different levels (in-process, in-factory, water industrial symbiosis, cross-sectorial) are established, considering also different water sources. These demonstration schemes are designed, monitored and evaluated using systemic methodologies and tools, based on holistic modelling concepts.

iii. DIGITAL INNOVATION: The novel concept of a water-specific Cyber-Physical-System (WaterCPS) synthesises digital twins of industrial and value chain entities to provide advanced water-saving awareness and optimised water efficiency at different industrial levels. Based on analytics-AI-learning methodologies, WaterCPS brings in cognitive-manufacturing methods and tools for dynamic process adaptation after route-cause analysis for detecting non-optimal water use, in order to continuously minimise fresh water consumption and emissions. Underlying WaterCPS, a real-time monitoring and distributed data management system connects the physical and digital worlds through smart sensor networks, IIoT and cloud/edge technologies.

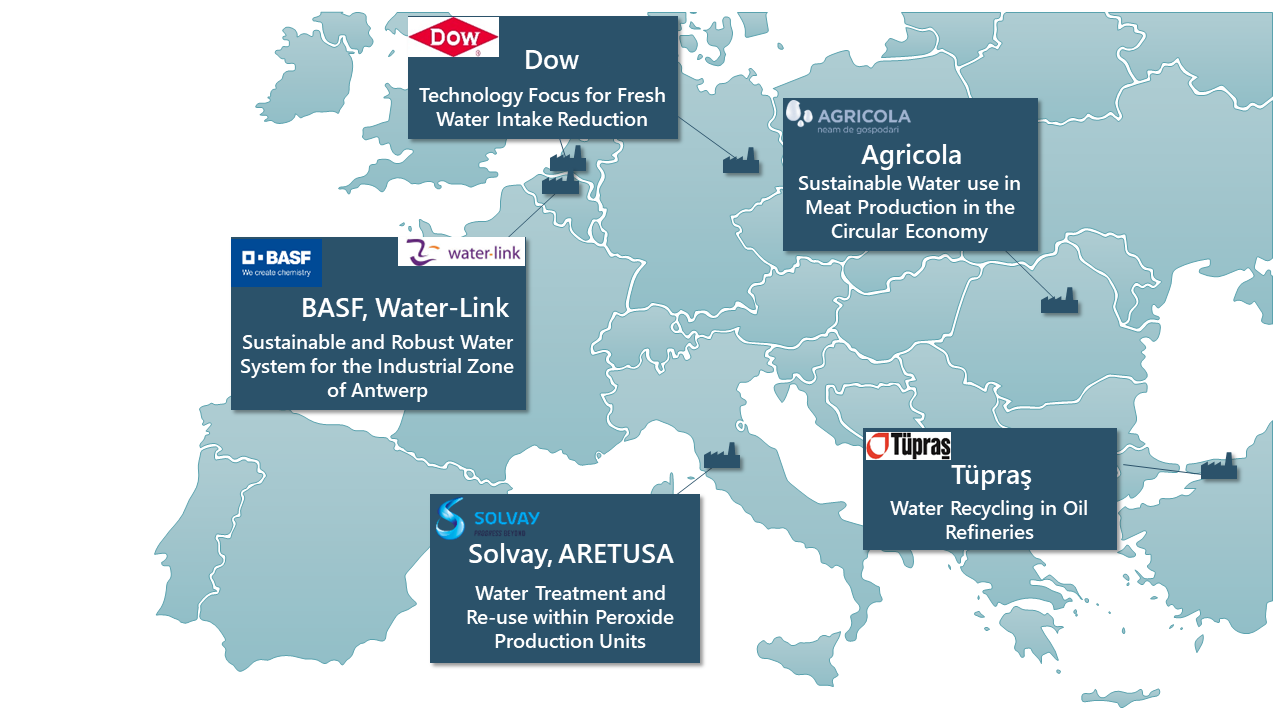

AquaSPICE’s innovations emanate from the requirements of the Case Studies, involving seven (7) industrial actors (Dow, BASF, Water-Link, Solvay, ARETUSA, Agricola and TUPRAS) in EU countries (Germany, Netherlands, Belgium, Italy, and Romania) and an associated country (Turkey).

AquaSPICE follows a systemic approach in water management where efficiency can be achieved through an adaptation of appropriate technologies and practices on different levels. Closed loops of water, substances and energy can be established on different levels: a single industrial process (unit operation), the entire factory, other collaborating industries (industrial symbiosis) or other sectors (e.g. domestic and/or agriculture).